Custom-designed Watercolor Storage

Published on Oct 17, 2025 (edits)

Jacques Lucke

More than a year ago, Vivien and Julien (both artists at the Blender Studio) showed me that they were designing a storage solution for Vivien’s watercolors. Existing storage solutions apparently had aspects left to be desired. This post briefly describes the design process and also comes with a generator at the end that allows anyone to build their own boxes.

Problem and Requirements

Once you have a certain amount of watercolor pans, they can’t be stored loosely in a box anymore. A lot of them are made with honey and stick together if piled up. Also, it takes forever to dig for the one you are looking for!

The ideal solution had to keep the pans neatly separate and visible, be modular and stackable to save precious desk space. Also, it would be best if a mix of pans and half pans could be organized together. We had to consider some variety of measurements between all the European and American manufacturers and 3D printed pans. After taking all the measurements we aimed for as little wasted space no matter how you combined pans, but also some wiggle room for easy reshuffling.

The other requirement was enough swatching space. It’s good to see a sample of each paint and potentially some notes about pigments and hide that under a layer of acrylic glass for splash protection. Since I have my pigment info listed elsewhere I currently only use this spot for swatching.

— Vivien Lulkowski

Design Process

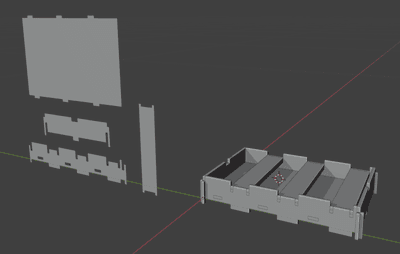

Originally, they were working on a 3D-printable design in Blender. This generally works, but the printing of large boxes takes a while, and they were also not entirely happy with the design yet. I recently learned about laser cutters before that and found that it may be better to design the storage solution for manufacturing with a laser cutter in mind. This can result in a simpler design that’s also much faster to produce in bulk (assuming the availability of a laser cutter of course).

Not having done anything like this before, I tried to sketch out my basic idea in Blender. For that I also used the CAD Sketcher add-on which was also the first time I used any CAD tools ever. I was pleasantly surprised by how well that went. The most tricky aspect was design it so that everything fits and remains stackable. Doing the design in 3D instead of just on paper helped a lot with that.

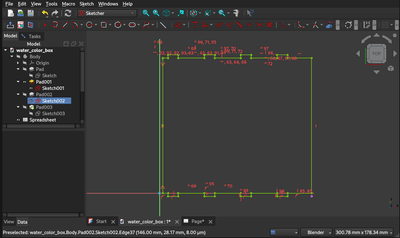

Later on, I also recreated the design in FreeCAD. That was mainly a learning exercise since I never used FreeCAD before either. I was also hoping to iterate in the design more easily there and have it be easier to export the design as .svg. In the end the initial idea for the design worked out surprisingly well though.

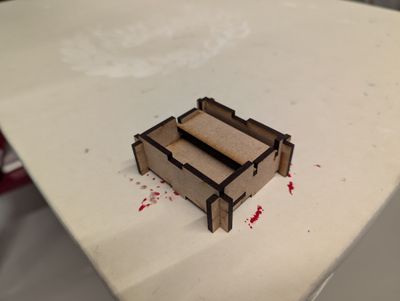

After producing the first box, we noticed that the dimensions were not ideal yet. The design also had a weak point as shown in the image at the bottom (part of the side piece is broken off).

Final Design

The final design is made up of four different pieces (floor, left/right, front-back and inlays). Everything can be made out of wood (3mm MDF in our case), except for the covers for the color samples which are made out of acrylic (also 3mm thick).

Producing a single box with a laser cutter takes just a few minutes. It’s also very easy to produce them in bulk.

Assembling a box can be done in about a minute and requires no extra tools or glue. Although one can reenforce the contacts with glue of course.

I was really happy with how the boxes turned out since they solve all the listed issues for me and on top of that they are lightweight, cheap to produce and quick to put together and disassemble! The concept seems really shareable as my troubles with piles of pans aren’t unique among other watercolorists and I haven’t encountered a solid solution to the problem, especially within a reasonable budget.

One minor thing that could be improved is a spot where the wood gets a bit weak after repeated disassembly and could break off, but the boxes don’t become unusable because of this. Also in my case I could just as well glue them once I don’t need to take them apart anymore.

— Vivien Lulkowski

Generator

The generator below creates .svg files required for manufacturing the box with custom dimensions. Especially the material thickness might need to be adjusted to get a good fit. In my case, just using the exact thickness of the material (3mm) happened to work well without further adjustments.

Note, the generator does not deduplicate lines currently. So you might want to do that yourself when producing lots of boxes to safe time. However, it should work fine without deduplication. Alternatively, you can also just add a gap between the individual pieces manually.

If you try to build this yourself, please share the result and/or problems with us!

The design is licensed under CC BY 4.0. Credit goes to Vivien Lulkowski and Jacques Lucke.

Main Dimensions

Material Thickness

Counts

Other

Previews